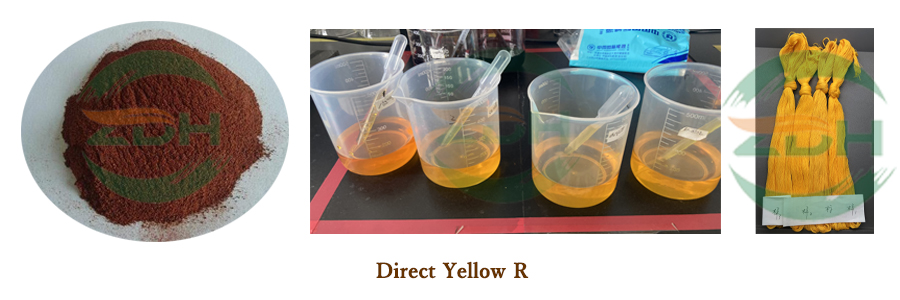

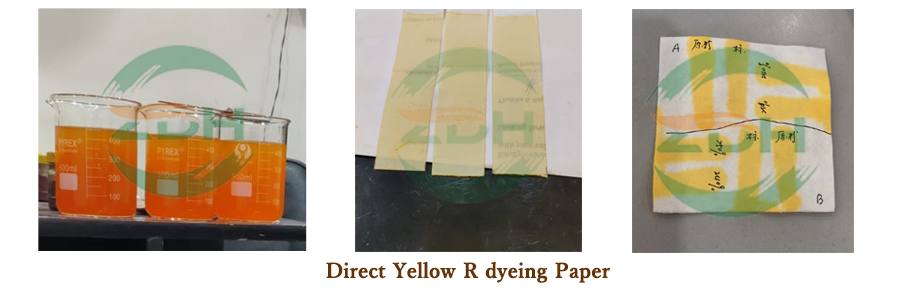

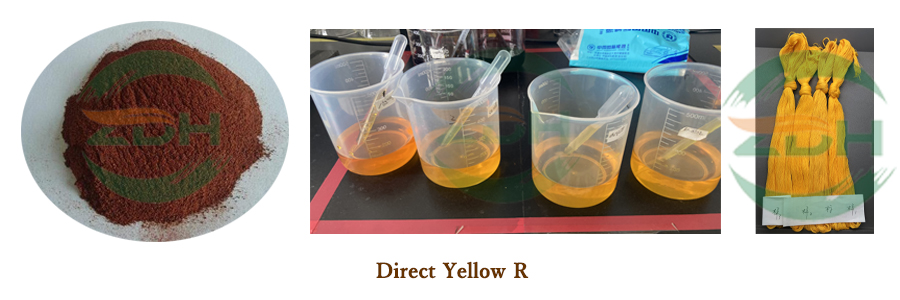

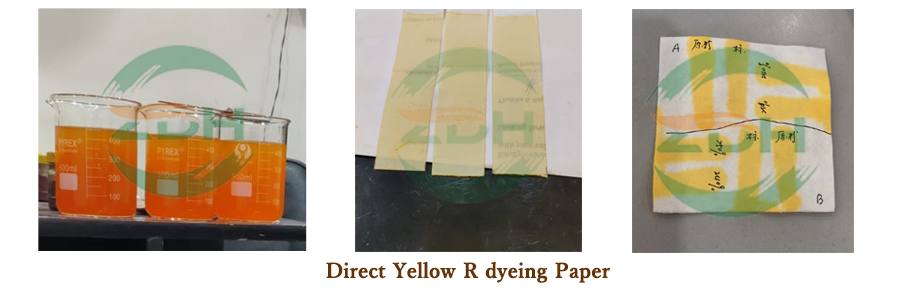

1. Direct yellow R is used to dye cotton or viscose fiber fabrics with bright red light yellow. Its levelness and migration are poor. When dyeing, salt should be added to control the dye uptake in order to obtain uniform color. After dyeing, the dyeing bath should be naturally cooled to 60~80 ℃ to facilitate dye absorption. After dyeing, the fastness to wet treatment can be improved by fixing agent treatment.

2. Direct yellow R can also be used for dyeing silk and wool. When it is used for dyeing blended fabrics, the color of silk and wool is much lighter than that of cotton and viscose fiber, acrylic fiber is slightly stained, and nylon, diacetate fiber and polyester fiber are not stained.

3. Direct yellow R is generally not used for the printing of cotton and viscose fabrics, nor for the ground color discharge printing.

4. Direct yellow R is mainly used for dyeing viscose silk and silk interwoven fabric. Soap soda bath dyeing can make silk white.